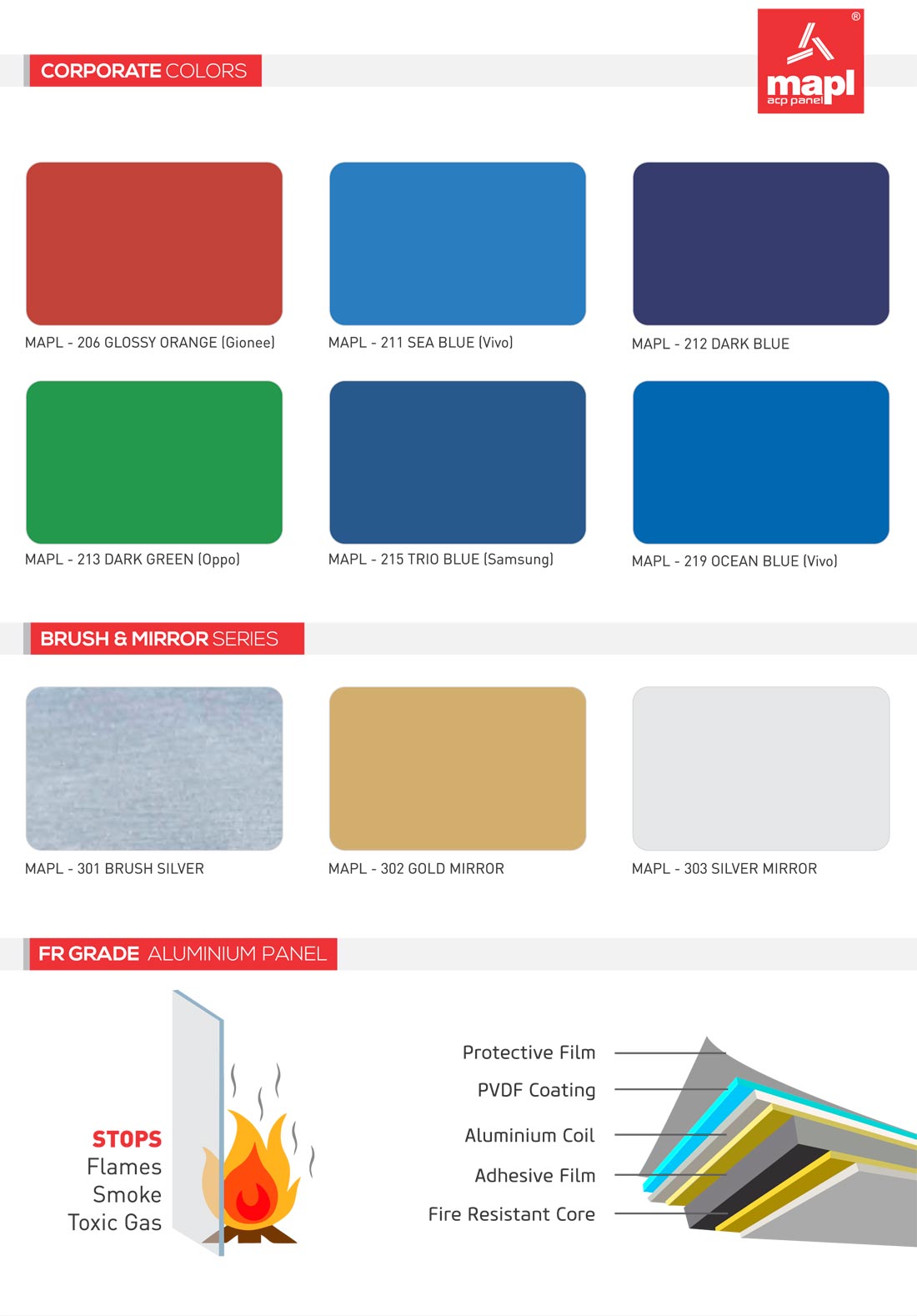

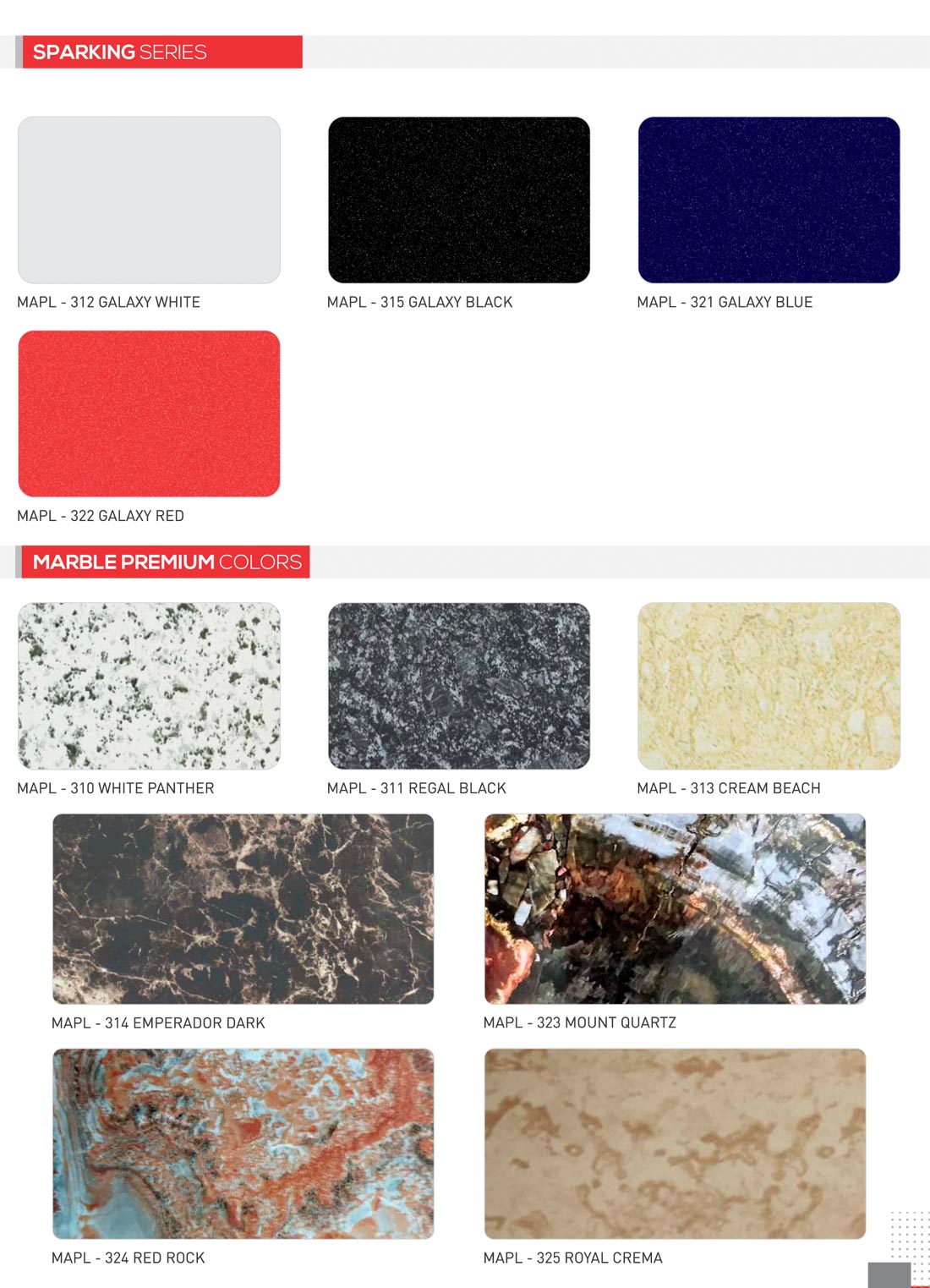

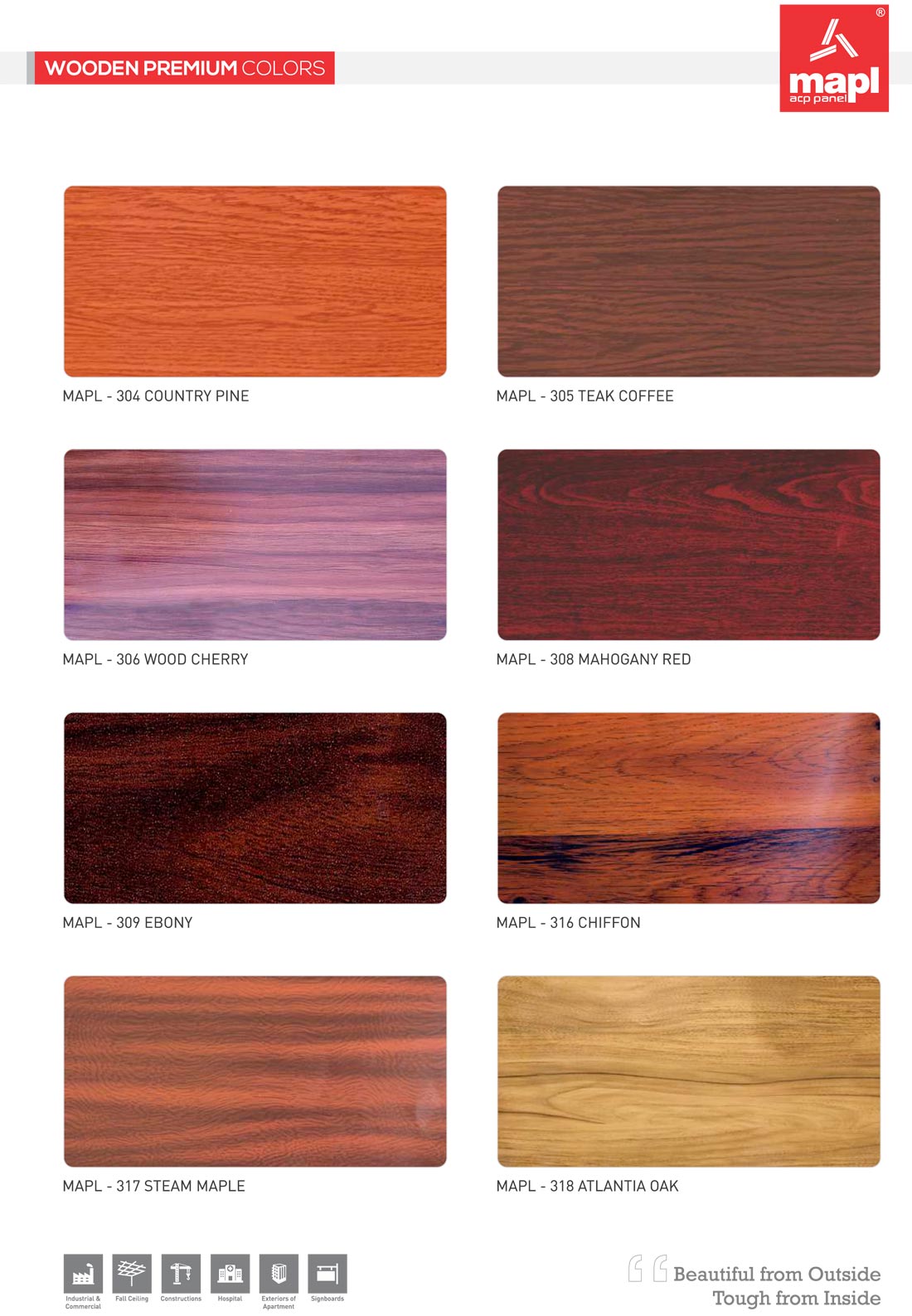

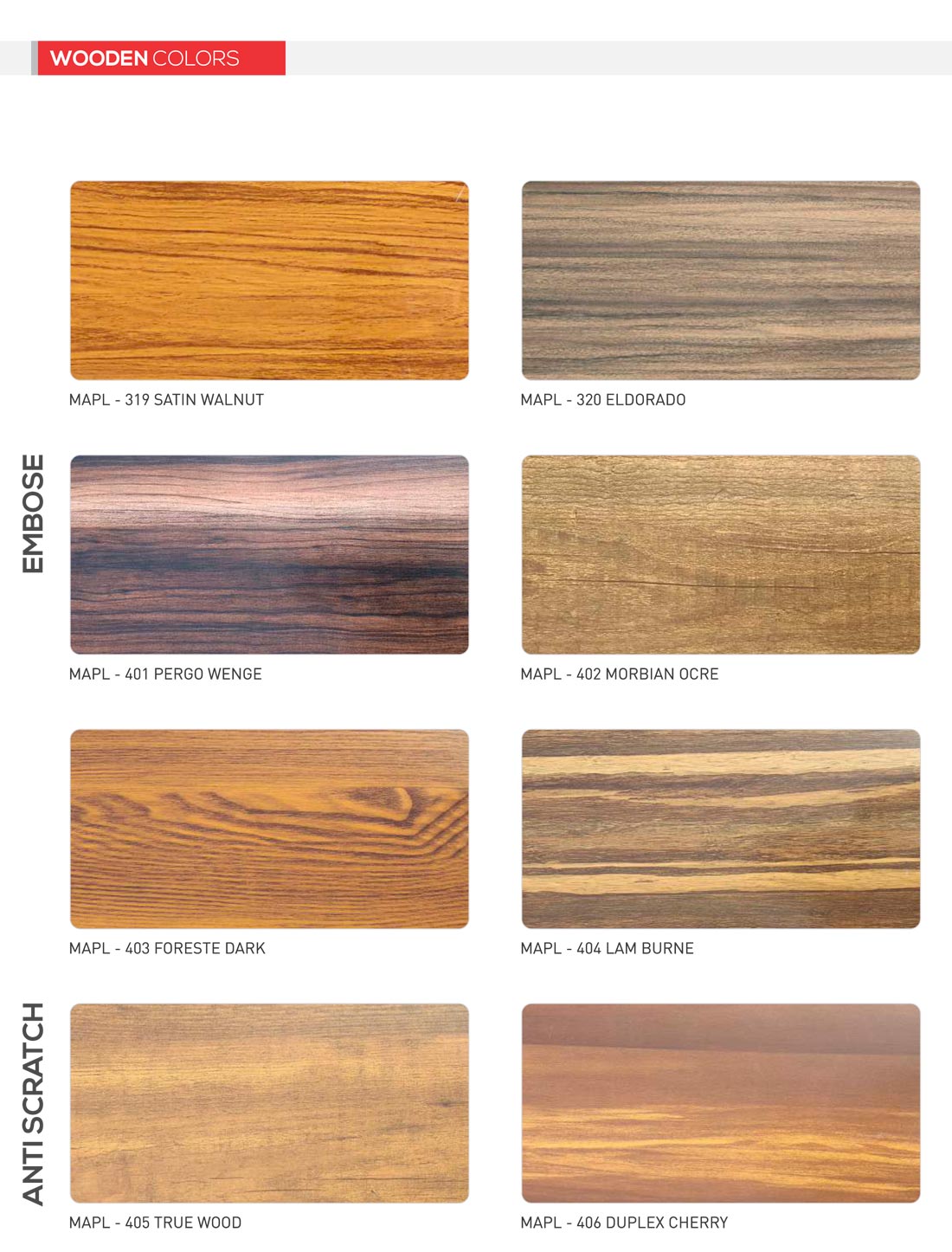

Products Aluminium Composite Panels

Distributors of -

- * HYNA DECOR

- * HYNA BOND

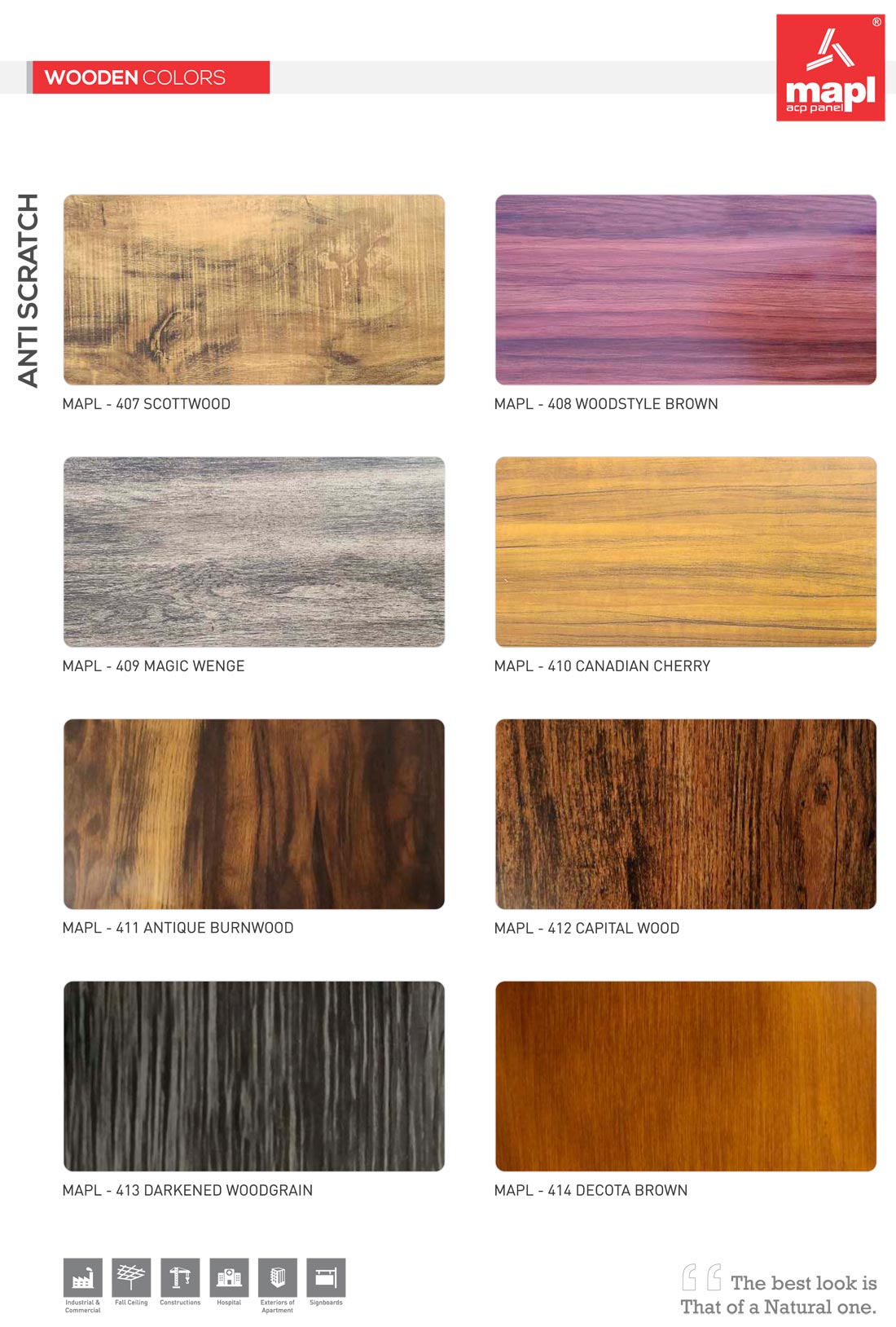

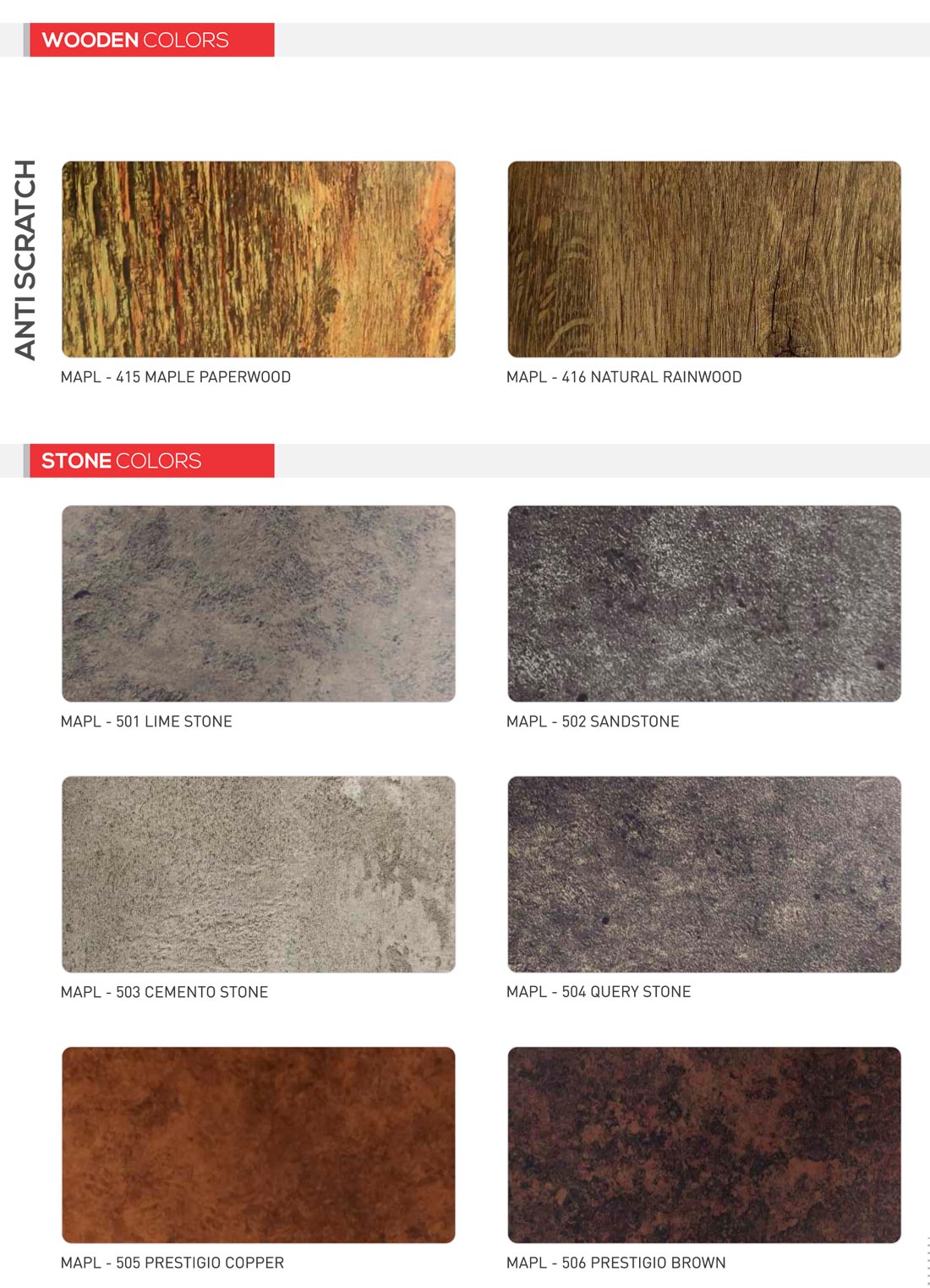

- * MAPL :

- Aluminium Composite Panel,

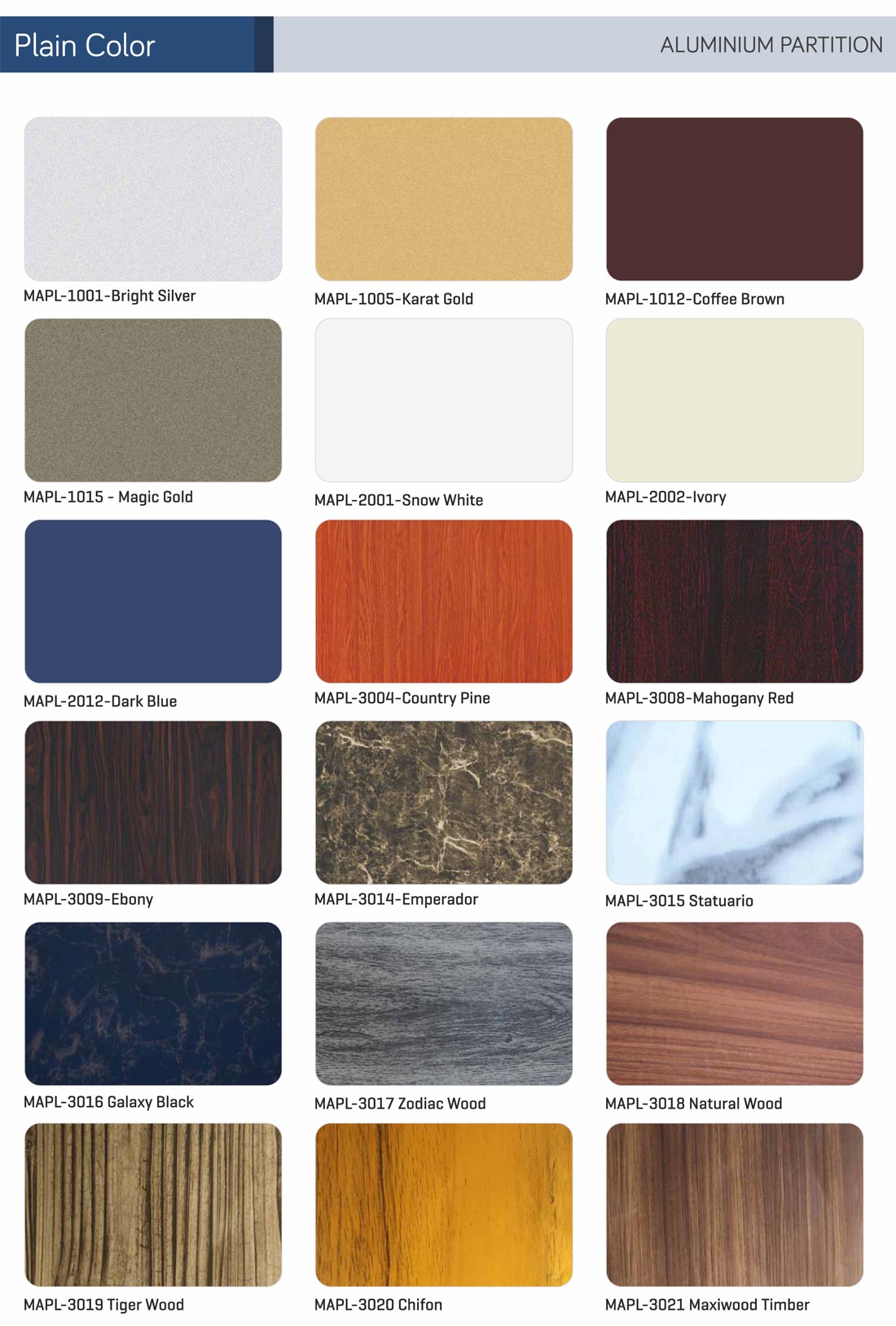

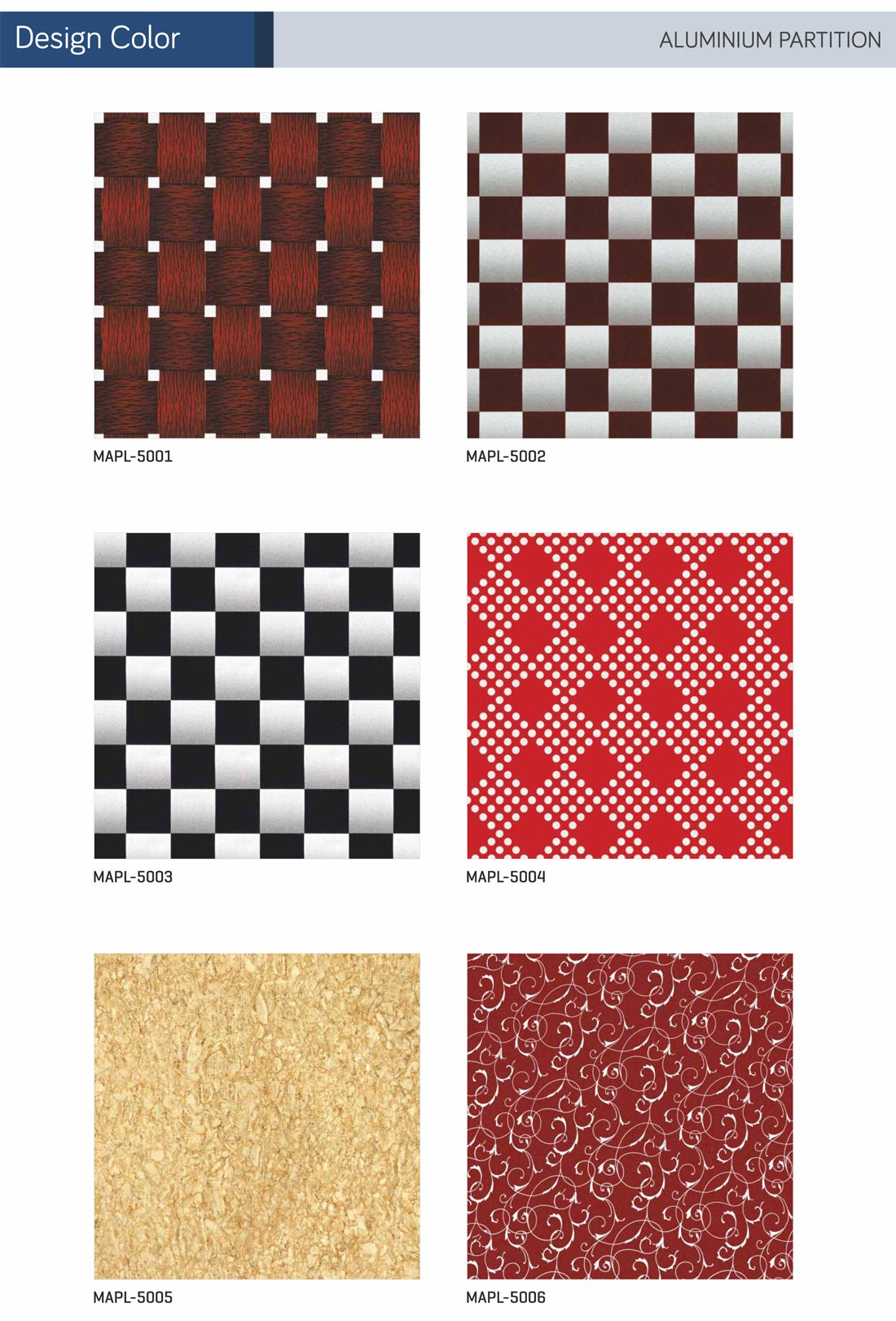

- Aluminium Partition Panel,

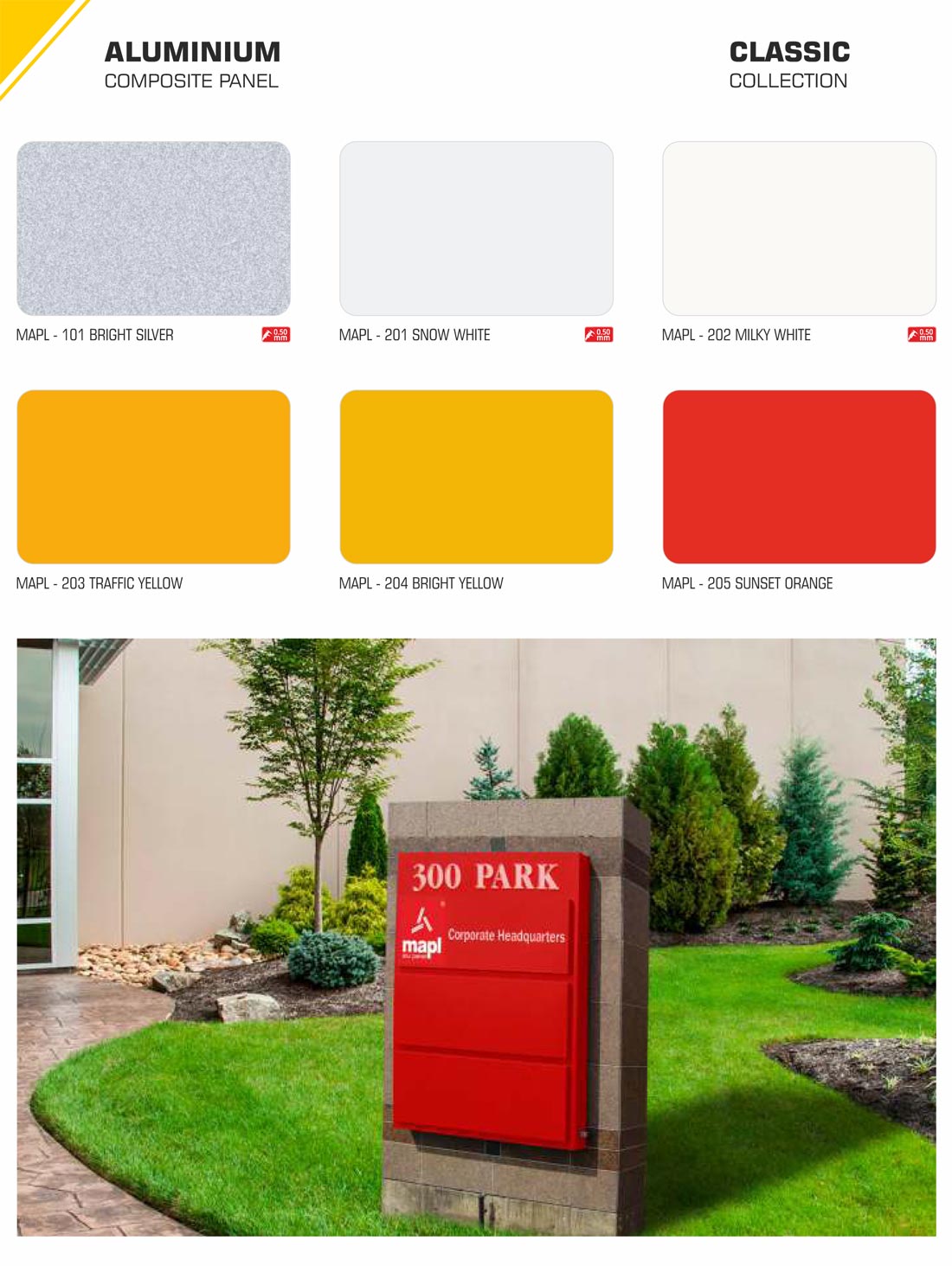

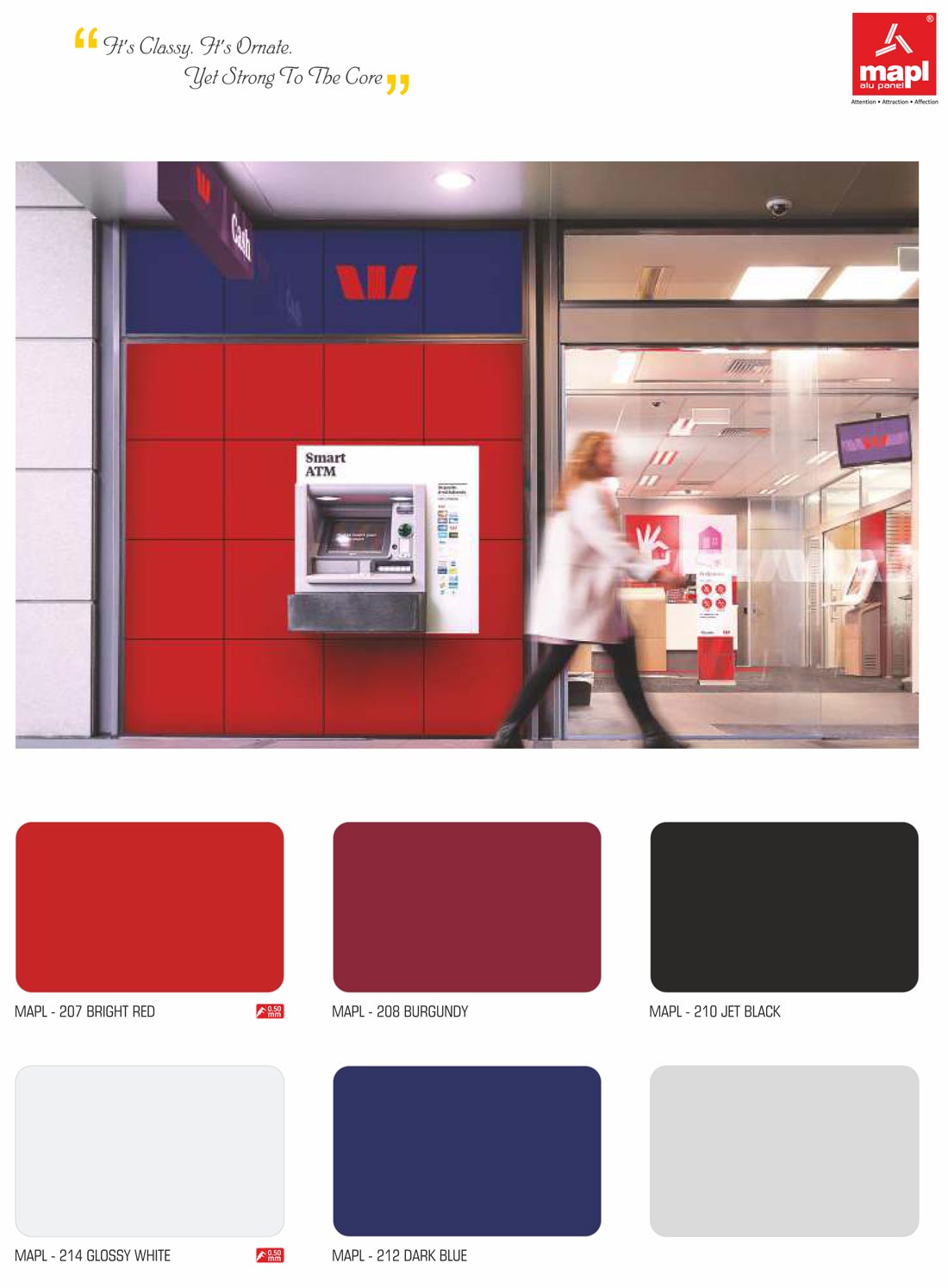

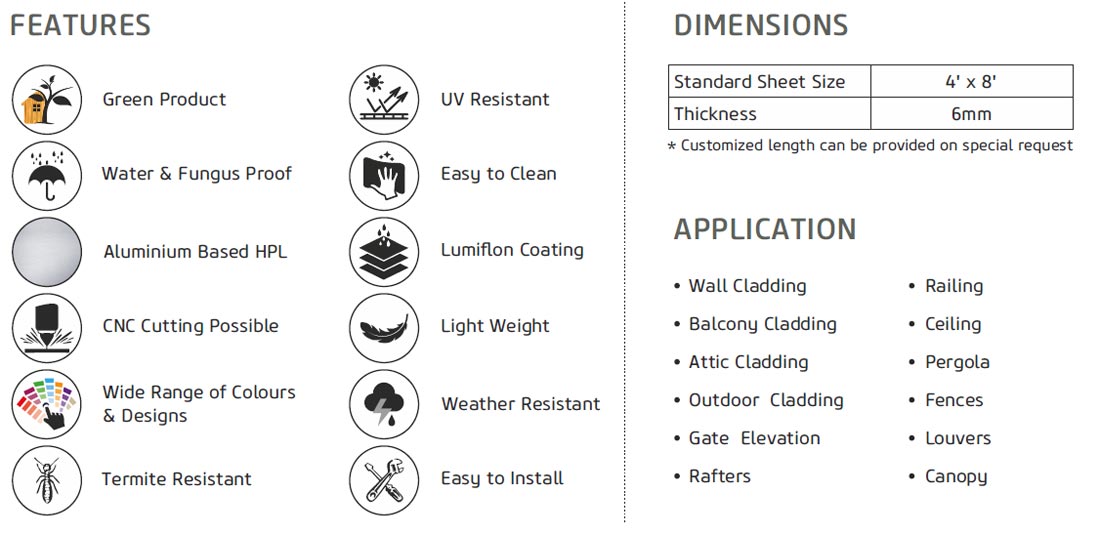

- Aluminium Composite Panel Classic Collection

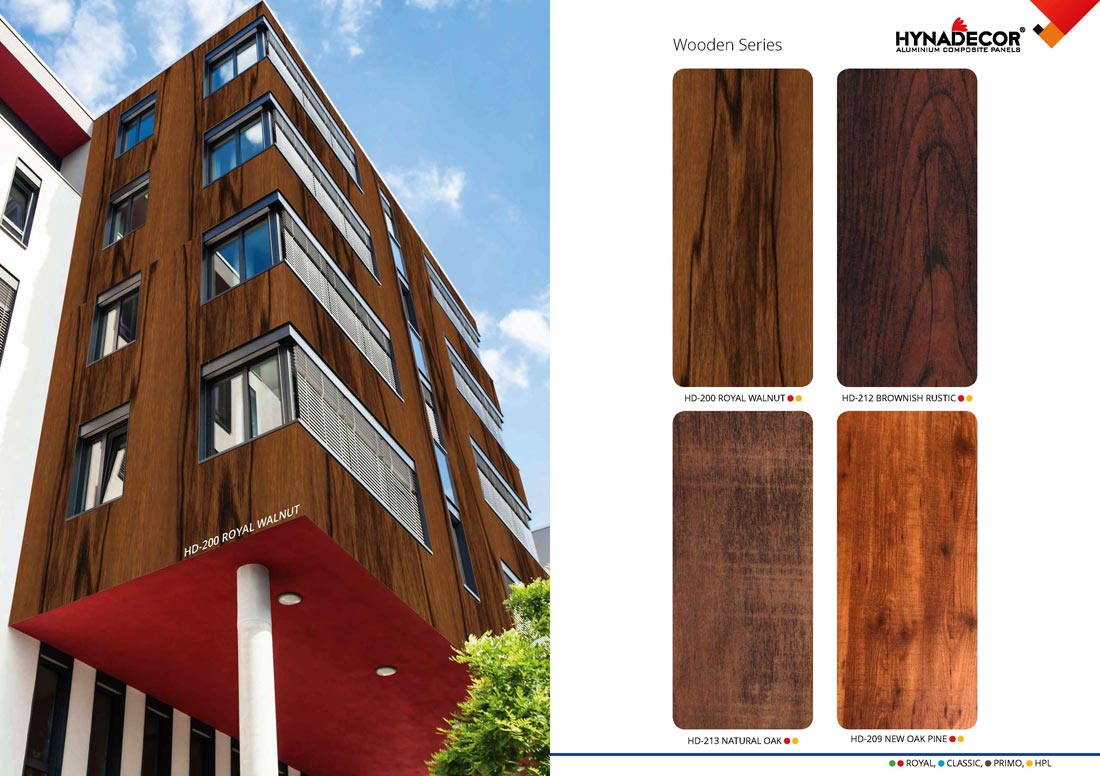

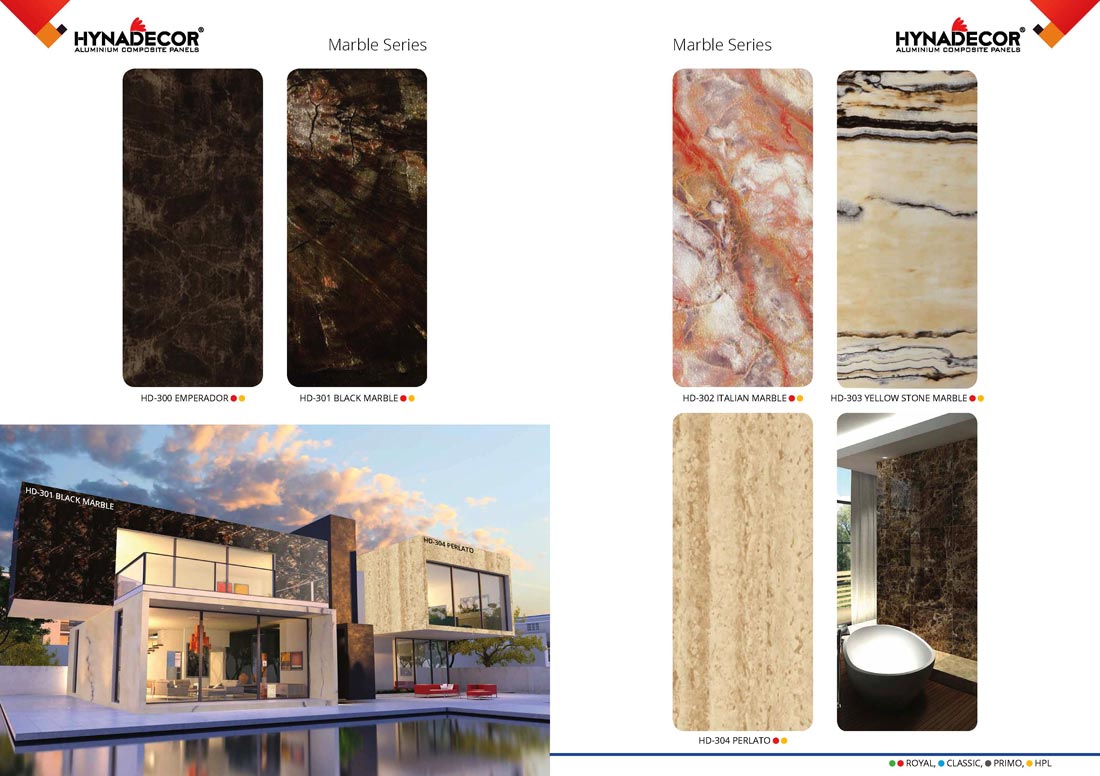

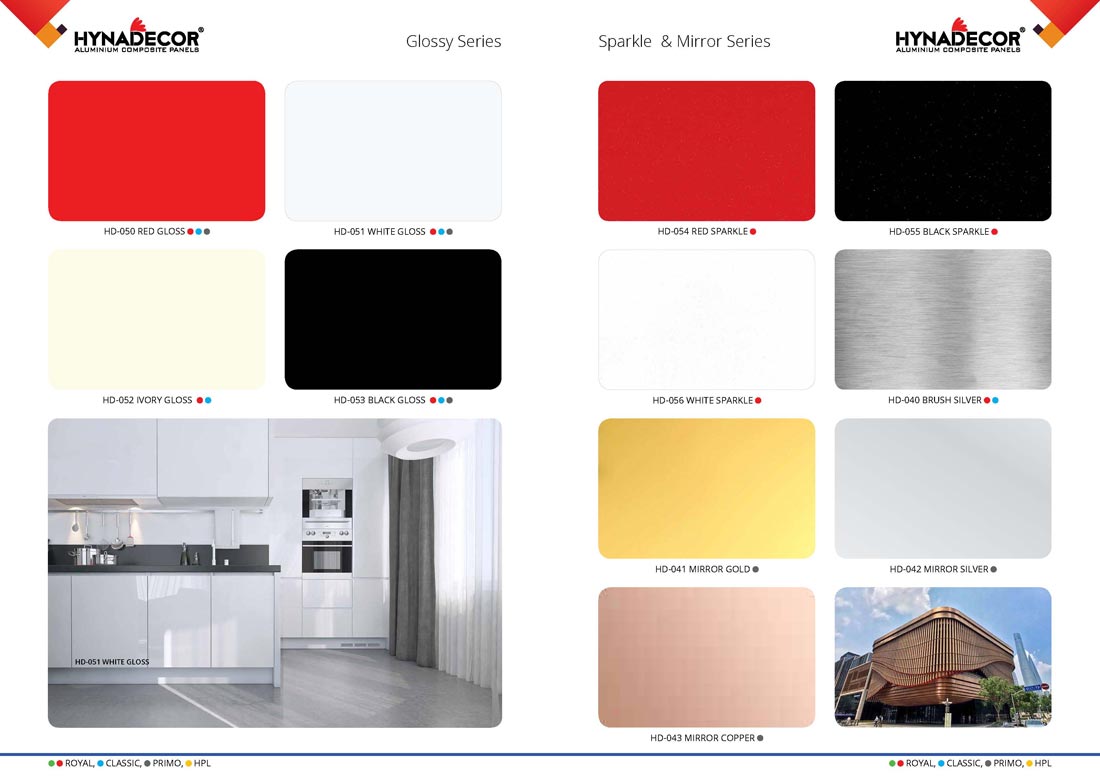

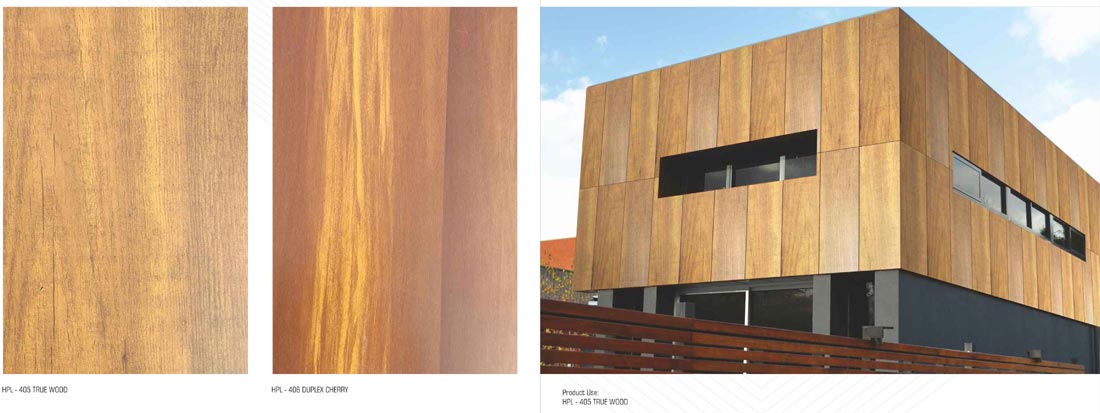

- Natural finish with Amazing design

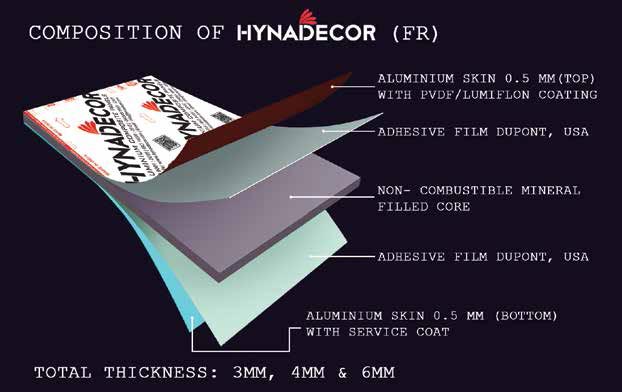

Hynadecor (FR) is an Aluminium Composite Material (ACM) for exterior cladding. It’s composed of core material and aluminium skins. The core material contains a non-combustible mineral and small content of thermoplastic, which ensures high performance of fire safety of this material. The skin is 0.5mm thick aluminium of 3005 H-16. The surface is finished with high-performance PVDF/Lumiflon-based paint and the back is a service coating. We use high-performance PVDF/Lumiflon-based fluorocarbon paint for the surface coating, ensuring both high durability and consistent coating quality. PVDF/Lumiflon-based fluorocarbon coating has a coating warranty of 12 years.

The greatest concern in external cladding is upward flaming over a vertical exterior wall, particularly in high-rise buildings. Various types of fire tests are required to examine the fire performance and non-combustibility of building materials. HYNADECOR (FR) not only passes all tests, but it is also certified to meet NBC for external cladding without any height restrictions.

GENERAL SPECIFICATION

| DIMENSIONS | MEASUREMENT |

| Thickness | 3mm, 4mm, 5mm, 6mm (±0.2mm) |

| Width | 1200mm (±2mm) |

| Length | Less than 6000mm (±4mm) |

| Bow | Max 0.5% of any dimensions |

| Diagonal Lines Difference | Max 5mm |

| MECHANICAL PROPERTIES | STANDARD | MEASUREMENT |

| Tensile Strength | ASTM D-638 | 49MPa |

| Yield Strength | ASTM D-638 | 44MPa |

| Bending Strength | ASTM C-393 | 120MPa(4mm) |

| Flexural Elasticity | ASTM C-393 | 2.6X104(4mm) |

| Shearing Strength | ASTM D-732 | 33MPa |

| Penetrating Resistance | ASTM D-732 | 11 kN |

| Adhesive Peel off Strength | ASTM D-903 | 10N/MM |

| Wind Pressure resistance | ASTM E-330 | Passed |

| Resistance against water | ASTM E-331 | Passed |

| Resistance against air | ASTM E-283 | Passed |

FIRE RESISTANT ACP

| GRADE | STANDARD |

| Class - A2 | EN13501 -1,s1,dO ASTM - E119 |

| Class - B | EN13501-1,s1, dO ASTM -E119 |

| Class - B1 | DIN4102 |

| Class - 0 | BS476 |

HYNADECOR A2 FIRE RETARDANT ACP

FIREPROOF ALUMINIUM COMPOSITE PANEL

HYNADECOR A2 fireproof metal composite panels are FIRE RETARDANT product as per En135501- 1,s1,do & ASTM - E119. It is covered on both sides with PVDF coated aluminium sheets, and embedded in between with natural inorganic materials. The inorganic material content is >-90% off the core, with balance made of virgin LDPE.

The metal sheet and core are perfectly bound by a special macromolecule binder. The advance process

technology of HYNADECOR produce the perfect FIRE RETARDANT CORE also improves the panels

mechanical feature as Highest grade of FIRE RESISTANCE ACP, toughness, impact resistance and crushing

resistance, which therefore ensure. That the ACP resists fire for minimum 2 hours with No MOLTEN

DROPLETS & NEGLIGIBLE SMOKE.

FIRE RESISTENCE CHARACTERISTICS

The material classifies to “Reaction to Fire” is Compliance with EN13501-1:2007+A1:2009 Classified as A2-s1,d0. Available in The thickness of 3.00 mm to 6.00 mm with overall weight of 8.50 kg/mt2 (for 4.00 mm ACP with coil of 0.50 mm on eithder side)

PRODUCT SPECIFICATION - ACP

|

PARTICULARS | PRODUCT COMPOSITION | |||||

★ |

Product Grade | • • Royal | • Classic | • Primo | HPL | ||

★ |

Total Thicknessof the panel | R45 | R43 | R33 | C33 | P23 | |

★ |

• | • | • | • | • | 6.0 mm | |

| 4.0 mm | 4.0 mm | 3.0 mm | 3.0 mm | 3.0 mm | |||

★ |

Thickness of the Aluminium Skin (Top & Bottom Skin) |

0.50 mm | 0.25 mm | 0.20 mm | 0.15 mm | 0.25 mm | |

★ |

Thickness of LDPE/ Mineral Core |

3.0 mm | 3.50 mm |

2.50 mm |

2.60 mm | 2.70 mm | 5.50 mm |

|

Product Tolerance |

Width | Length | Thickness | Squareness | Bow | |

★ |

0/±4.0 mm | 0/±6.0 mm |

3.0mm | Max 5.0mm | 0.5% of Length & Width |

||

★ |

Grade | Exterior | Exterior | Interior | Exterior | ||

★ |

Warranty* | 12 Years | 7 Years | - | 12 Years | ||

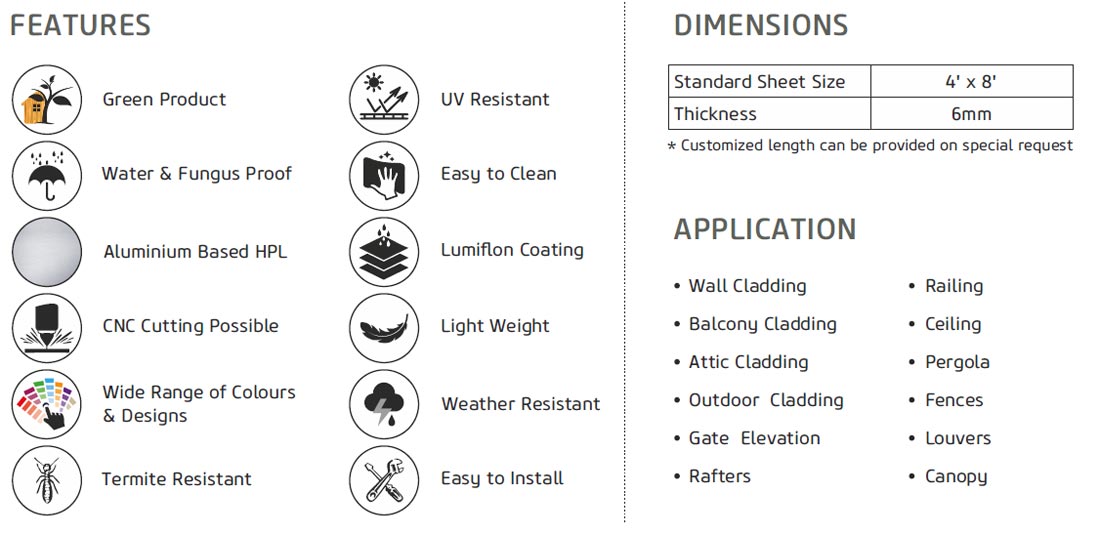

HYNABOND Partitions Panels are robust, water and termite resistance and can be utilized for optimization of spaces in all domestic and commercial establishments like offices, hospital, shopping malls, etc. It is available in 15 colours with 4mm thickness and can also be effectively used in wet areas like laboratories, kitchens, washrooms, toilets, laundries, places that have high human traffic, etc.

HYNABOND Partition Panel with stands pressure and ensure years of stability. HYNABOND Partition Panels are in demand from various domestic and industrial customers and are the preferred choice for kitchen, balcony, washroom and other areas where water is in regular contact.

ADVANTAGES OF PARTITION PANEL

- 100 % Water proof.

- It’s robust & termite proof.

- No wrapping & bending tendency.

- Maintenance Free.

- Excellent Sound & thermal Insulation.

- Long lasting.

- It can also be effectively used in high humidity spaces like laboratories, toilets, laundries kitchens, washrooms, healthcare units & even toilets areas where water is in regular contact.

HAULING, HANDLING & STORAGE

To ensure there is no damage to the edges or surface of the high-end material (MAPL HPL), please handle them with extreme care. During the process of transporting the panels, they should be protected well against slipping. Make sure that the panels are lifted securely while handling or unloading them. Kindly avoid pushing or pulling them over the edge.

It's important to remove the protective film within 45 day of installation.

The panels must be stocked parallel to the ground on flat and stable supporting panels. They should be in completely flat position. Erroneously storing the panels can lead to permanent damage or deformation.

TECHNICAL SPECIFICATIONS

Technical Specifications Of MAPL |

||

| S. No. | ITEMS | MAPL HPL |

| 1 | Thickness of composite panel (mm) | 6mm |

| 2 | Skin Thickness (mm) | 0.25mm |

| 3 | Weight (Kg/Sqm) | 7.5g |

| 4 | Polyethylene type LDPE (g/cm3) | 0.92 |

| 5 | Surface | ------ |

| 6 | Lacquering | LUMIFLON/PVDF |

| 7 | Brilliance (Initial Value) | 30-30% accord to Gardner |

| 8 | Hardness (Pencil Hardness) | H |

| 9 | Temperature resistance | from -50°C to +80°C |

| 10 | UV stability | Brilliant |

Mechanical Properties of ACM |

||

| S. No. | ITEMS | MAPL HPL |

| 11 | Tensile Strength (ASTM E-8) | 3.2 KgmP2 |

| 12 | Yield Strength (ASTM E-8) | 4 Kg/mm2 |

| 13 | Elongation (ASTM E-8) | 13% |

| 14 | Flexural Elasticity (ASTM C-393) | 4030/MM2 |

| 15 | Thermal Expansion (ASTM D-698) | 1.1 mm/M/50.0 |

Mechanical Properties of Aluminium Skin |

||

| S. No. | ITEMS | MAPL HPL |

| 16 | Aluminium Alloy Grade | H 18 - 1 100 |

| 17 | Yield Strength | 14 Kg/mm2 |

| 18 | Modules of Elasticity (ASTM C-393) | 7000 Kg/mm2 |

| 19 | Bond Integrity (ASTM C-297) | 118 Kg/cm2 |

| 20 | Deflection Temperature (ASTM D-698) | 110°C |

Accoustical Properties |

||

| S. No. | ITEMS | MAPL HPL |

| 21 | Sound Absorption Factor as | 0.05 |

| 22 | Airborn sound insulation index Rw (dB | 24 |

| 23 | Loss Factor D | 0.0057 |

Accoustical Properties |

||

| S. No. | ITEMS | MAPL HPL |

| 24 | Gloss at 600 | 26 |

| 25 | Elongation ASTM E-8 | A50>=3% |

| 26 | Abrasion Resistance (ASTM - D- 968-81) | The painted film doesn't wear out through pouring 50 litre of sand on the surface of the coated panel. |

| 27 | Hardness (Pencil hardness) | 3H |

| 28 | Film Hardness (Pencil hardness) | 2H |

| 29 | Rigidity E-J (KN cm 2/3) | B65 |

| 30 | Reverse Impact Crosshatch ASTM01737-62 |

2T1 No Cracking |

ADHESION |

||

| S. No. | ITEMS | MAPL HPL |

| 31 | Dry ASTM D-3359 Method 8 | No Change |

| 32 | Wet 37.80C, 24 Hrs | No Change |

| 33 | Boiling Water 1000C, 20mm | No Change |

Mechanical Properties of Aluminium Skin |

||

| S. No. | ITEMS | MAPL HPL |

| 34 | HCL (ASTM D 1 309 | No Change |

| 35 | H2 So4 (ASTM Dl 308-79) | No Change |

| 36 | Detergent (ASTM D2248-73) | No Change |

| 37 | Oil Resistance | No Change |

| 38 | Dirt Resistance | No Change |

WEATHER ABILTY |

||

| S. No. | ITEMS | MAPL HPL |

| 39 | CoLour Retention ( ASTM D-2244-89 Max 5 Units) |

4000 Hrs |

| 40 | Gloss Retention ASTM D-523-89 70% | 4000Hrs |

| 41 | Chalking ASTM D-4214-89 Max 8 Units | No Chalking was Seen 4000Hrs |

| 42 | Salt Spray | No Change 3000Hrs |

| 43 | Humidity ASTM D-2247-87 | No Blister, No Cracking 10 Cycles:24 Hrs X 100% RH, 37.80C2 HrsX 180C |

| 44 | Humidity (Thermal ASTM D-2244-65 | None to very few It blisters 100% |

| 45 | Condensing Humidity 54.40C ASTM 4585-87 |

Rhx 54.40C, 2500 Hrs |

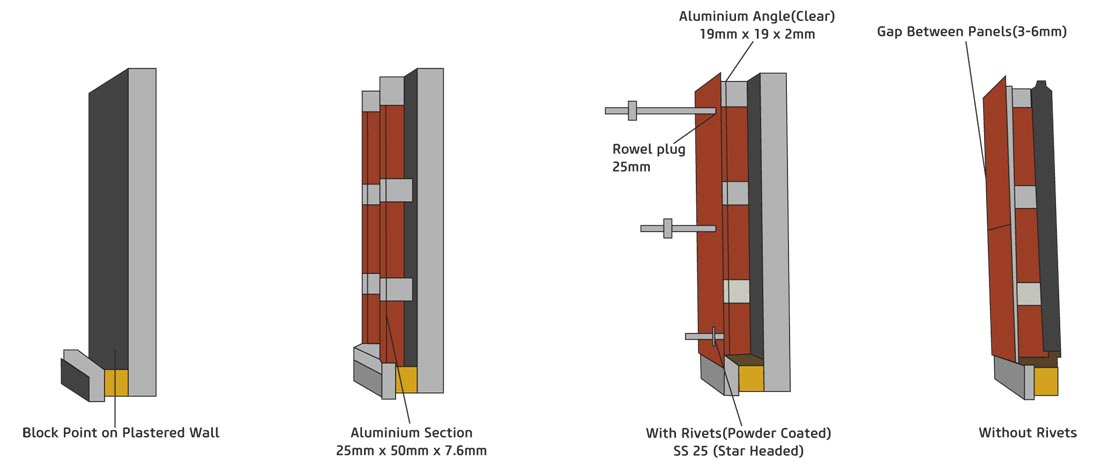

FIXING METHOD

| Thicknessof Sheet | Minimum Distanceof Holes to the Edge | Maximum DistanceBetween the Holes - Width | Maximum DistanceBetween the Holes - Length |

| 6mm | 10-20mm | 450mm | 550 |

Fixing Details (with Rivets)

- Block Panel and Plastered Wall

- Fix aluminium section on wall, estimation gap of 400- 700mm, center-to-center with help of deal vertically

- Pilot hole must be drilled before fastening rivets light

- Size of rivets must be three times the thickness of panel and gauge of aluminium; ensure rivets used are fully threaded

Fixing Details (without Rivets)

- Slightly rub off the surface of aluminium section and portion of panels with the help of sandpaper before applying adhesive on it

- Don't use any silicon in the gap filling

- Maintain a gap of 3mm-6mm in between the plan